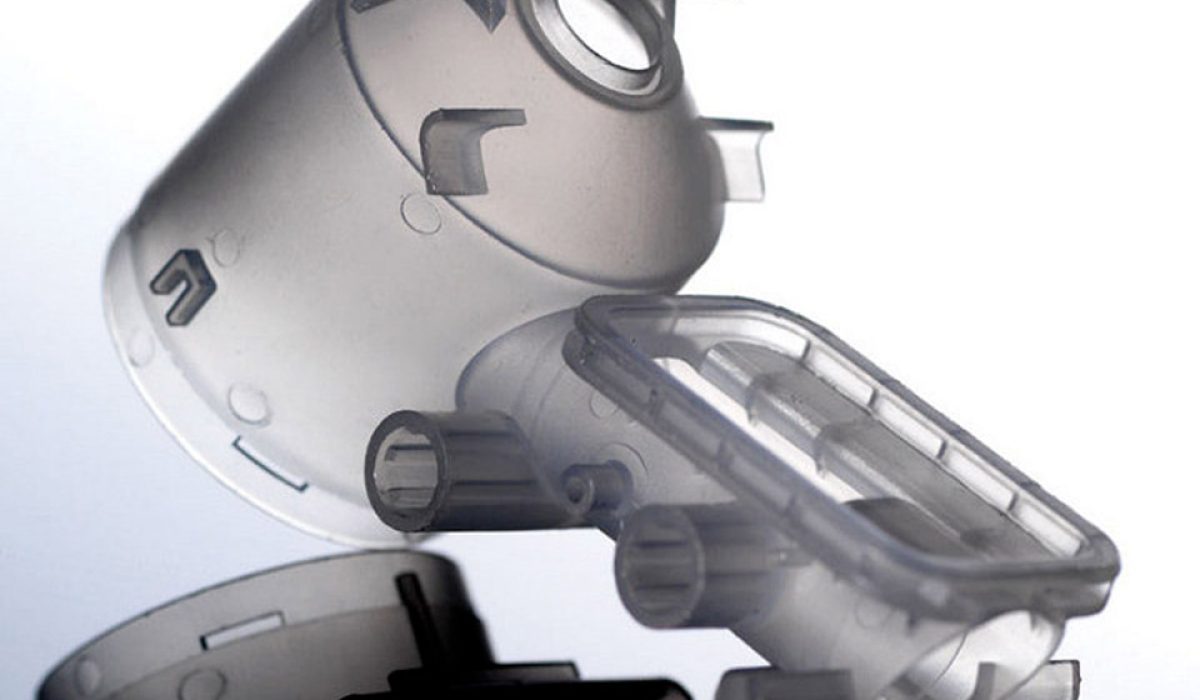

For MEDICAL applications, precision moulds for technical parts combined with high-performance materials (PEEK, PEI, PPS, PPAA, PAA, LCP, etc.)

For medical markets, the integrated skills of the DPH team can anticipate all shape details of the part to be manufactured well in advance of project completion to ensure quality and optimised cycle times.

Here are the replies from Joël Theuriau, General Manager of DPH.

The importance of working well in advance

Before the technical part project, we assist our designer or injector customers to optimise production and its effectiveness. « We can already see the mould when we look at the part» . Being part of the design phase helps us to take into account better all the marketing and commercial criteria of the specification so that the technical and economic solution best suited to the budget and production quantities is found. »

Appropriate solutions developed jointly

The medical field is a significant part of our business. When we are asked to assemble different parts, we work with the project team to ensure without fail that they are mountable, safe and tamper-proof. We produce tools using different technologies, multi-materials, overmoulding of plastic or metal inserts to produce highly-technical parts.

A strong point: cooling optimisation

One of the strengths of our approach is to optimise in order to reduce cycle times, using cutting-edge technologies like laser fusion and conformal cooling. « With these technologies, productivity and quality are the order of the day, insofar as parts coming out of the mould do not need deburring, which is reassuring for our customers.» The DPH machinery is renewed regularly to suit the high-precision requirements of projects.

Please contact Joël Theuriau. if you also are interested by this approach that adds value to your tools in creating technical parts.